Smart Industry Solution

Monitor your machines and production processes. Analyze your energy consumption and environment conditions. Optimize operating costs and save unexpected expenses.

Monitor your machines and production processes. Analyze your energy consumption and environment conditions. Optimize operating costs and save unexpected expenses.

Monitor your machines and production processes. Analyze your energy consumption and environment conditions. Optimize operating costs and save unexpected expenses.

Smart Industry Solution enable Industry 4.0 standards with a combination of top quality IoT sensors and software application for effective real-time monitoring of your production processes, assets and working environment.

Our solution is designed for a complete monitoring of your production facility – energy consumption, waste and material flow, workplace and machine conditions.

Smart Industrial Solutions enable Industry 4.0 standards with a combination of top quality IoT sensors and software application for effective real-time monitoring of your production processes, assets and working environment.

Smart Industry Solution enable Industry 4.0 standards with a combination of top quality IoT sensors and software application for effective real-time monitoring of your production processes, assets and working environment.

Our solution is designed for a complete monitoring of your production facility – energy consumption, waste and material flow, workplace and machine conditions.

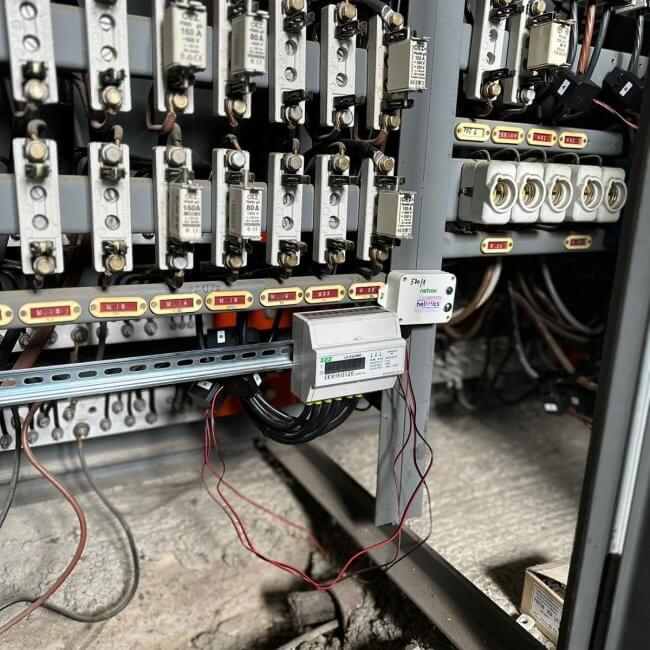

Gain real-time insights into energy usage and consumption peaks, increase energy efficiency, and reduce costs.

Take control of your energy consumption and reach new levels of productivity. Elevate your facility to a high-performance manufacture.

Water flow

Electricity

Gas

Water flow

Electricity

Gas

Gain real-time insights into energy usage and consumption peaks, optimize efficiency, and reduce costs.

Take control of your energy consumption and unlock new levels of productivity. Elevate your facility to a high-performance manufacture.

Water flow

Electricity

Gas

Identify patterns of energy consumption across different production processes and equipment.

Analyze the collected data to optimize energy usage, streamline operations, and improve overall production efficiency.

Detect abnormalities in energy consumption that may indicate equipment malfunctions.

React early by indetifying such issues and schedule preventive maintenance to avoid downtime and production interruptions.

Implement energy-saving measures by adjusting equipment settings or production schedule optimization.

Discover areas for improvement, lower energy waste, and reduce environmental footprint.

Identify patterns of energy consumption across different production processes and equipment.

Analyze the collected data to optimize energy usage, streamline operations, and improve overall production efficiency.

Detect abnormalities in energy consumption that may indicate equipment malfunctions.

React early by indetifying such issues and schedule preventive maintenance to avoid downtime and production interruptions.

Implement energy-saving measures by adjusting equipment settings or production schedule optimization.

Discover areas for improvement, lower energy waste, and reduce environmental footprint.

Track the assets in your production throughout the whole cycle. Prevent overflows, optimize resource utilization, and streamline production planning.

Monitor the production process from the beginning till the end and control:

– raw material levels

– material weight

– production waste

– inventory tracking

– in-transit tracking

Waste containers

Material flow

Warehouse tracking

Waste containers

Material flow

Warehouse tracking

Track the assets in your production throughout the whole cycle. Prevent overflows, optimize resource utilization, and streamline production planning.

Monitor the production process from the beginning till the end and control:

– raw material levels

– material weight

– production waste

– pallets tracking

– in-transit tracking

Waste containers

Material flow

Warehouse tracking

Analyze waste generation and respond early to the needs of emptying.

Optimize collection schedules, reduce unnecessary operational costs, and minimize environmental impact by making waste management more efficient.

Prevent production disruptions and enable more efficient material processing.

Monitor the levels and volumes, manage containers, tanks and storage, and streamline the production with real-time data.

Track the movement and quantity of material throughout and outside the production process.

Operate with accurate inventory data, ensure smooth supply process, and minimize stockouts.

Analyze waste generation and respond early to the needs of emptying.

Optimize collection schedules, reduce unnecessary operational costs, and minimize environmental impact by making waste management more efficient.

Prevent production disruptions and enable more efficient material processing.

Monitor the levels and volumes, manage containers, tanks and storage, and streamline the production with real-time data.

Track the movement and quantity of material throughout and outside the production process.

Operate with accurate inventory data, ensure smooth supply process, and minimize stockouts.

Create safer, healthier, and more productive work environments for your production facilities. Improve efficiency with real-time data about your workplace conditions.

Safeguards well-being of your employees and secure production continuity by optimizing key environmental factors by monitoring:

– temperature, humidity, CO2

– fumes, dustiness, noise

– leakage, smoke

Air quality

Workplace conditions

Security

Air quality

Workplace conditions

Security

Create safer, healthier, and more productive work environments for your production facilities. Improve efficiency with real-time data about your workplace conditions.

Safeguards well-being of your employees and secure production continuity by optimizing key environmental factors by monitoring:

– temperature, humidity, CO2

– fumes, dustiness, noise

– leakage, smoke

Air quality

Workplace conditions

Security

Take corrective actions with more reliable data from environment monitoring.

Regular monitoring helps ensure operation within legal limits, avoid penalties, and maintain social and environmental responsibility.

Identify presence and levels of pollutants, implement appropriate pollution prevention and control measures, and ensure required working conditions.

Safeguard the health of your employees in industrial settings.

Detect and control exposure to potential hazards, take proactive measures, and ensure occupational health and safety standards.

Take corrective actions with more reliable data from environment monitoring.

Regular monitoring helps ensure operation within legal limits, avoid penalties, and maintain social and environmental responsibility.

Identify presence and levels of pollutants, implement appropriate pollution prevention and control measures, and ensure required working conditions.

Safeguard the health of your employees in industrial settings.

Detect and control exposure to potential hazards, take proactive measures, and ensure occupational health and safety standards.

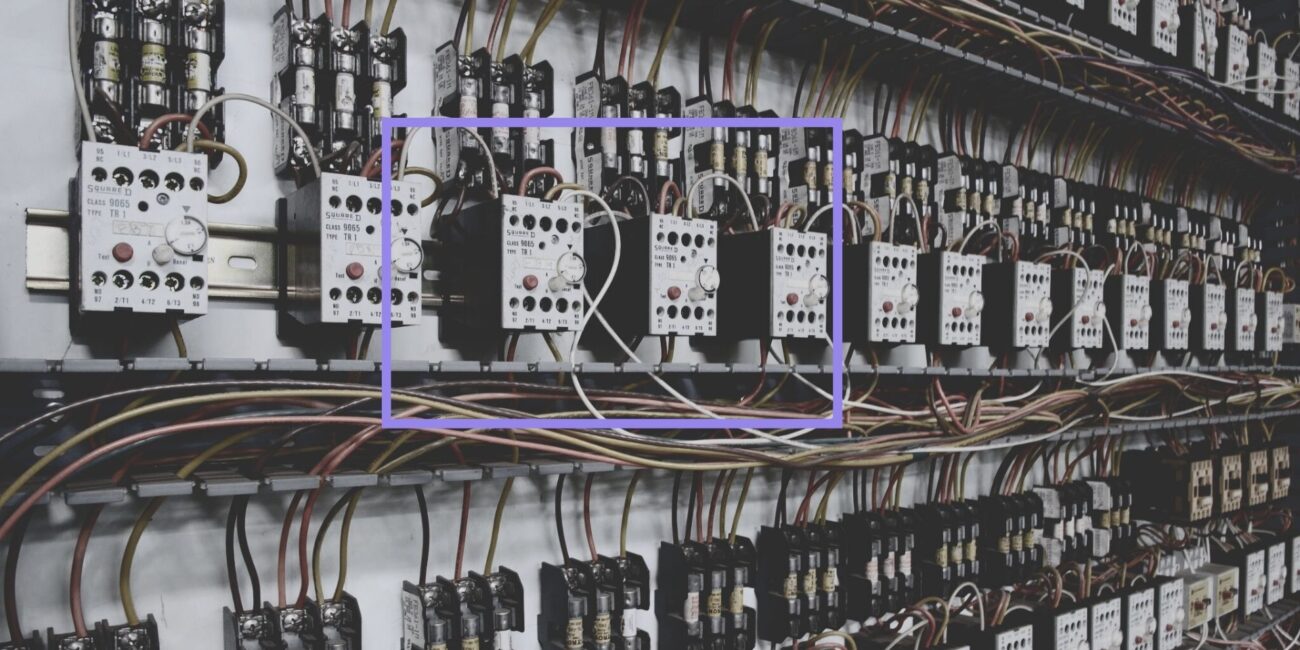

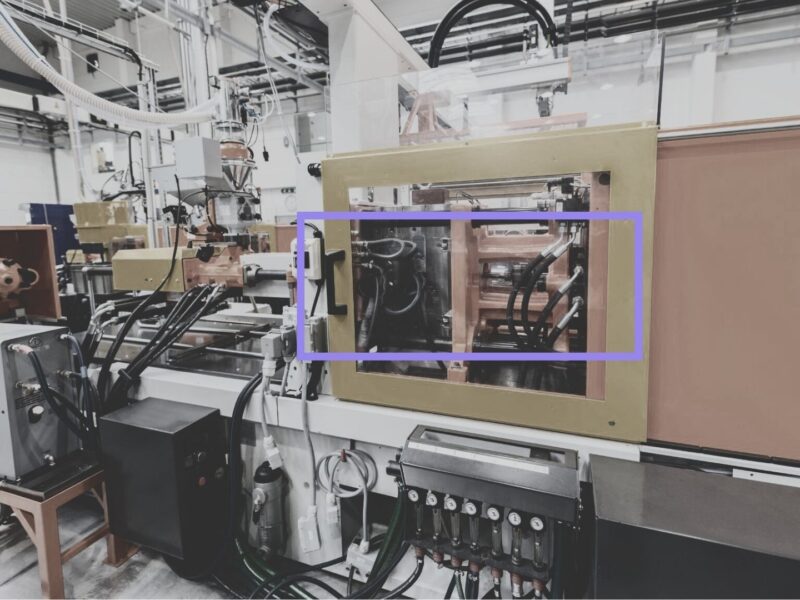

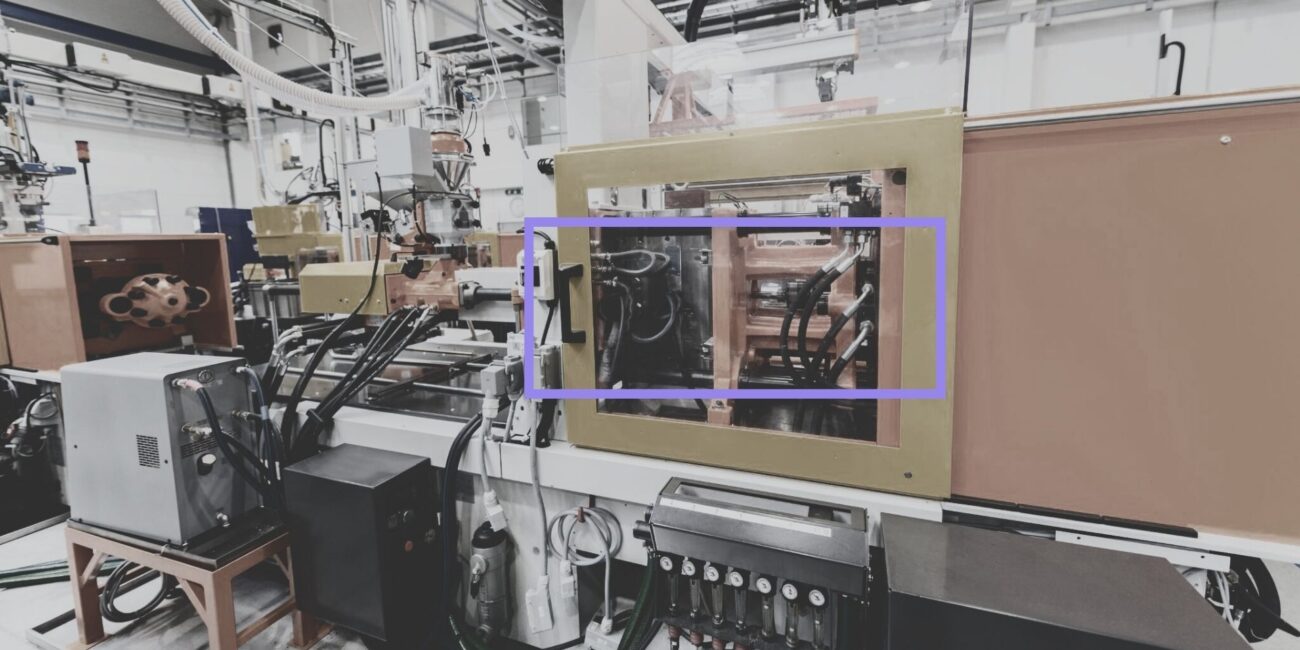

Recognize the critical importance of machine reliability and performance in your production facility.

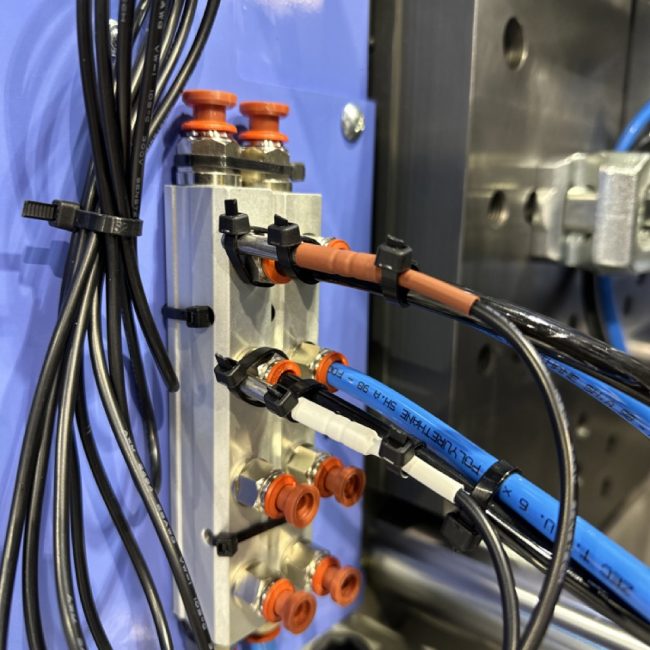

Make most of the full potential of your machinery and stay informed about their functional conditions by detecting and controlling:

– machine parts temperature, vibrations, and shocks

– machine downtimes

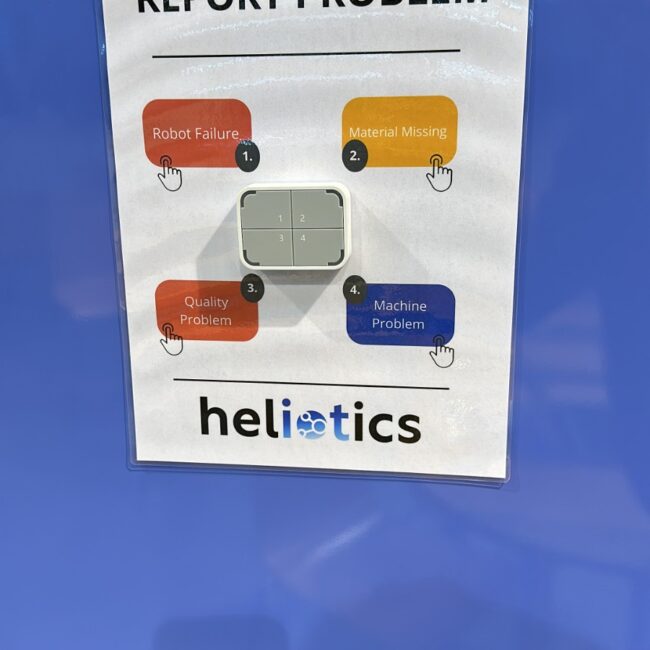

– reports for faulty machinery, missing material, or quality problems

– shift from preventive to predictive maintenance

Machine conditions

Predictive maintenance

Remote reporting

Machine conditions

Predictive maintenance

Remote reporting

Recognize the critical importance of machine reliability and performance in your production facility.

Make most of the full potential of your machinery and stay informed about their functional conditions by detecting and controlling:

– machine parts temperature, vibrations, and shocks

– machine downtimes

– reports for faulty machinery, missing material, or quality problems

– shift from preventive to predictive maintenance

Machine

conditions

Remote

reporting

Predictive

maintenance

Monitor machine conditions to secure proper operating performance.

React on time with alerts triggering abnormal operating conditions, excessive vibration or temperature, and prevent accidents.

Utilize data analytics about machine performance and operational trends.

Leverage the information for process optimization, resource allocation, and continuous improvement in production processes.

Detect issues before they cause malfunctions or harm to the equipment.

Prevent unplanned downtime, optimize maintenance practices and extend machinery lifetime.

Monitor machine conditions to secure proper operating performance.

React on time with alerts triggering abnormal operating conditions, excessive vibration or temperature, and prevent accidents.

Utilize data analytics about machine performance and operational trends.

Leverage the information for process optimization, resource allocation, and continuous improvement in production processes.

Detect issues before they cause malfunctions or harm to the equipment.

Prevent unplanned downtime, optimize maintenance practices and extend machinery lifetime.

Have complete insights about your production facility. Work with real data and make more informed decision.

Reduce unnecessary expenses, optimize your processes, and manage your resources in a more effective way.

With alerts and reports you know about unexpected changes, deviations or other emergency situations.

Monitoring devices are cableless and require no need to intervene with the machines during installation.

View all the information anytime from anywhere. With remote access the data are available online 24/7.

IIoT is for any industry. Automotive, manufacturing factories or industrial plants. It can be customized to any needs.

Have complete insights about your production facility. Work with real data and make more informed decision.

Reduce unnecessary expenses, optimize your processes, and manage your resources in a more effective way.

Monitoring devices are cableless and require no need to intervene with the machines during installation.

With alerts and reports you know about unexpected changes, deviations or other emergency situations.

View all the information anytime from anywhere. With remote access the data are available online 24/7.

IIoT is for any industry. Automotive, manufacturing factories or industrial plants. It is designed for any needs.

For additional information read through the information two-pager.

Do you want to start monitoring your production facility?

Start monitoring your machines and energy consumption, control workplace conditions, save unnecessary expenses, and optimize resources.

Do you want to start monitoring your production facility?

Start monitoring your machines and energy consumption, control workplace conditions, save unnecessary expenses, and optimize resources.